To learn more about our precision sheet metal fabrication capabilities, contact us today. Our engineers can work with a variety of metals, including aluminum, cold-rolled steel, hot-rolled steel, galvanized steel, and stainless steel. We can assist you in all aspects of fabrication, from CAD design and material selection to cutting and forming to welding and assembly to finishing and storage.

STEEL 18 GAUGE HOW TO

Want to learn more about sheet metal gauges and how to decipher them for your next metal fabrication project? The experts at T/J Fabricators have got you covered!Įquipped with extensive experience providing custom sheet metal fabrication services to customers across a wide range of industries, we have what it takes to meet all of your sheet metal manufacturing needs. The difference in thickness between 18-gauge and 20-gauge is 0.008 inches, while the difference in thickness between 18-gauge and 16-gauge is 0.010 inches.Ĭustom Sheet Metal Fabrication Services at T/J Fabricators For example, 18-gauge sheet metal made from aluminum is 0.040 inches, 20-gauge sheet metal made from aluminum is 0.032 inches, and 16-gauge sheet metal made from aluminum is 0.050 inches.

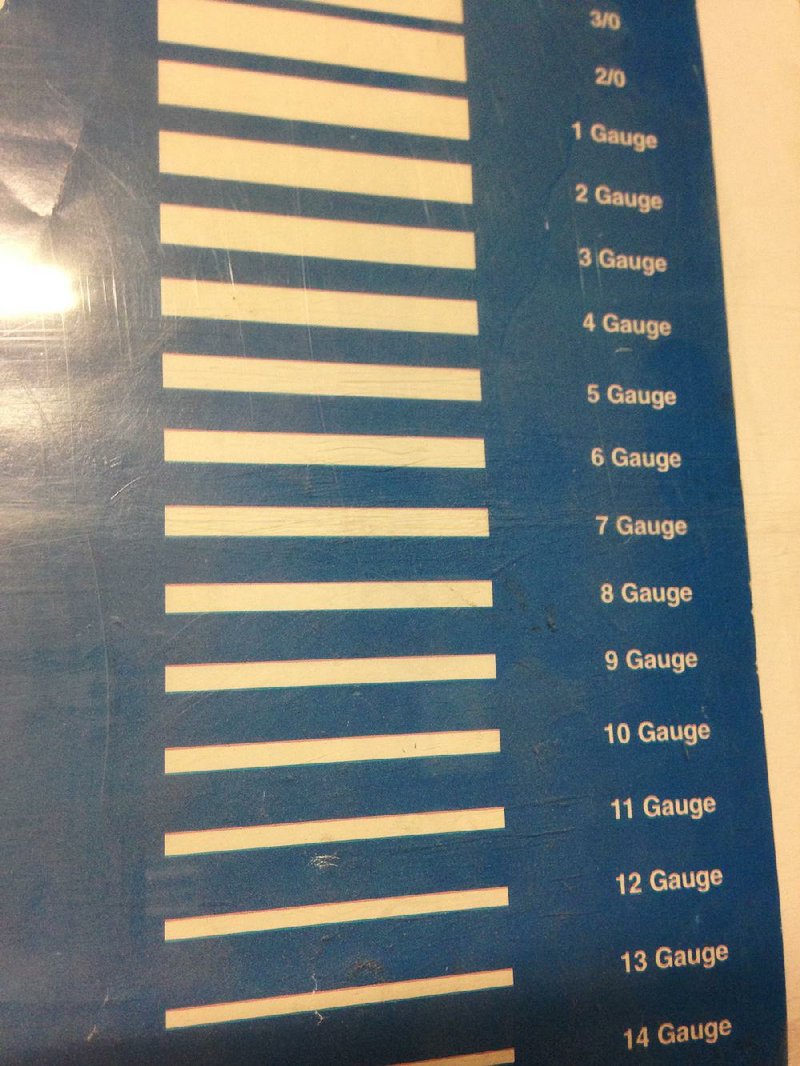

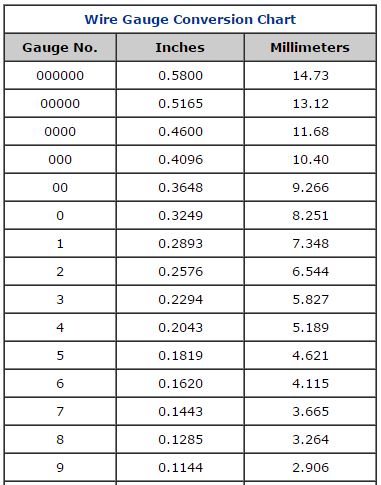

Sheet Metal Gauge Charts Carbon Steel Gauge Chart Gauge Numberĭownload Steel Sheet Metal Gauge Chart Stainless Steel Gauge Chart Gauge Numberĭownload Stainless Steel Sheet Metal Gauge Chart Aluminum Gauge Chart Gauge Numberĭownload Aluminum Sheet Metal Gauge Chart How to Read a Sheet Metal Gauge Chart

While this value is not provided in imperial or metric units, it can be converted to one or the other using a gauge conversion chart. The gauge of a piece of sheet metal refers to its thickness. It describes how it is used, provides conversion charts for various materials, and discusses how to read them. The following guide provides an overview of the gauge measurement system. Since the gauge measurement system is independent of both the imperial and metric measurement systems (i.e., a gauge value of 18 is not equal to 18 inches or 18 centimeters), someone unfamiliar with it may find it difficult to understand. While these might be the highest rated, what you choose should fit your needs, so consider features such as Brand, Finish and Gauge when making your selection. It is vastly used for many miscellaneous applications. Sheet metal is commonly described by gauge, which indicates the thickness of the particular piece of sheet metal. Galvanized steel sheet metal also known as just galvi, is made by coating regular steel sheets in zinc. So, remember, when you’re comparing safes, the smaller the steel gauge, the thicker the steel.Posted by wpengine on Ma8:38 am | Leave a Comment The different thicknesses may seem so close to one another that it wouldn’t matter, but each step up in thickness represents a big difference when it comes to safe security and fire protection. (32.4k) 9.99 bee nose ring, gold filled nose ring, small nose hoop, dainty nose ring, tiny nose ring, 20 gauge nose ring, 22 gauge nose ring, 6mm, 8mm (9.2k) 20. How Thick Is The Gauage of Steel?Įach gauge of steel represents a specific thickness. 19.98 316L Surgical Steel Nose Ring, Stud, Screw, L Bend or Nose Bone, Heart Paw Print. Thicker steel also improves the safe’s fire protection rating. It’s more difficult to cut through, and it makes the safe heavier and harder to tip over and pry open. Thicker steel obviously improves the safe’s security level. Being UL-listed is an important distinction for both safe locks and safe bodies. UL, or Underwriter’s Laboratories, is a third-party company that verifies claims companies make for their products. That’s why safes that aren’t at least 12 gauge steel or thicker cannot be UL-listed as Residential Security Containers (RSC). And the thickness makes a difference-the thicker the steel, the stronger it is. 7 gauge steel, for example, is much thicker than 12 gauge steel. The rating for steel gauge may seem backward: the smaller the number, the thicker the steel. Everything You Need to Know About Gauge of Steel

0 kommentar(er)

0 kommentar(er)